AEMWE OER®Anode electrode

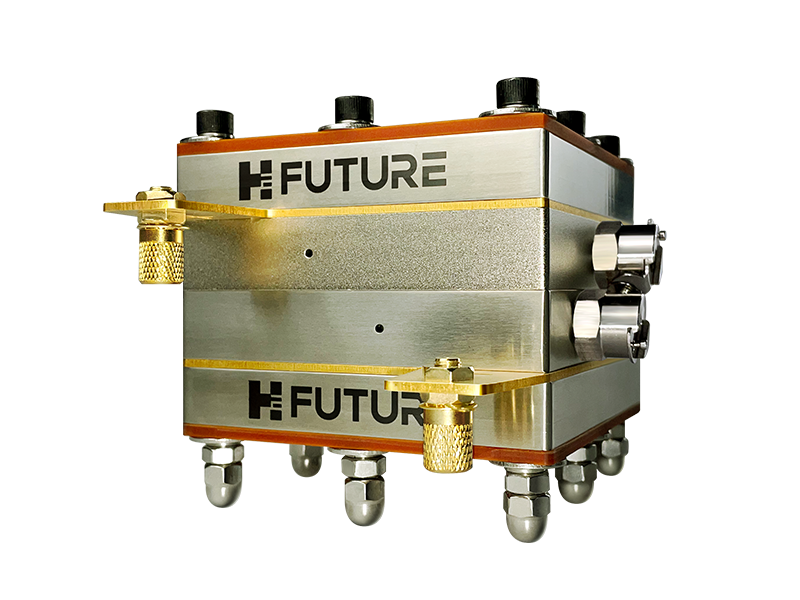

The dependence of anode electrodes on key raw materials and the degradation of activity in long-term operation have long plagued the hydrogen production industry. The future hydrogen energy AEMWE OER anode electrode, using non-precious metal materials, from the source to solve the key raw materials "stuck neck" problem. Not only with excellent catalytic activity and stability, it can maintain high efficiency performance in industrial hydrogen production for a long time, but also large-size anode electrodes can be prepared to meet the hydrogen production needs of megawatt electrolyzers, which can effectively promote efficient and economical electrolysis of water. Hydrogen production provides practical solutions for the future of green energy.

Classification:

Product characteristics

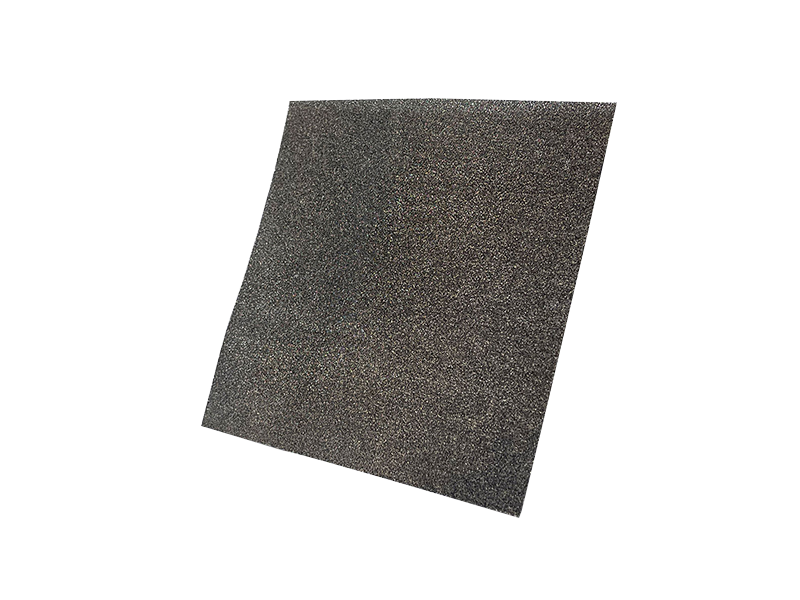

high catalytic activity

The surface of the catalytic layer is covered with 2μm pores, which greatly increases the hydrogen production sites. Under the same conditions, the efficiency of oxygen evolution is more than 10 times that of other catalysts.

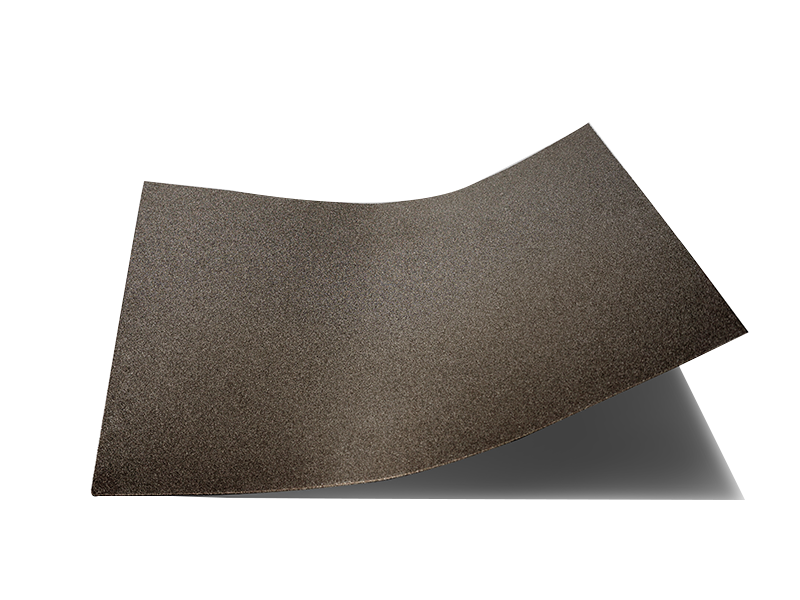

High stability

Stable operation for 5000h, the voltage attenuation is only 30mV, greatly improving the service life of the catalyst, which is 4-5 times that of other commercial catalysts.

Applicable MW grade electrolyzer

It can prepare large-size anode membrane electrode, with a maximum of 500x 500mm, which is suitable for hydrogen production demand of megawatt electrolyzer.

Product Parameters

| Product Name | AEM anode electrode |

| Substrate | nickel foam |

| catalyst component | Ni-Fe |

| Maximum product size | 500x500mm |

| Storage conditions | Vacuum seal before use |

| 200mA/cm² overpotential | 263mV |

Previous article:

The next one:

AEMWE OER®Anode electrode

The dependence of anode electrodes on key raw materials and the degradation of activity in long-term operation have long plagued the hydrogen production industry. The future hydrogen energy AEMWE OER anode electrode, using non-precious metal materials, from the source to solve the key raw materials "stuck neck" problem. Not only with excellent catalytic activity and stability, it can maintain high efficiency performance in industrial hydrogen production for a long time, but also large-size anode electrodes can be prepared to meet the hydrogen production needs of megawatt electrolyzers, which can effectively promote efficient and economical electrolysis of water. Hydrogen production provides practical solutions for the future of green energy.

所属分类:

Product characteristics

high catalytic activity

The surface of the catalytic layer is covered with 2μm pores, which greatly increases the hydrogen production sites. Under the same conditions, the efficiency of oxygen evolution is more than 10 times that of other catalysts.

High stability

Stable operation for 5000h, the voltage attenuation is only 30mV, greatly improving the service life of the catalyst, which is 4-5 times that of other commercial catalysts.

Applicable MW grade electrolyzer

It can prepare large-size anode membrane electrode, with a maximum of 500x 500mm, which is suitable for hydrogen production demand of megawatt electrolyzer.

Product Parameters

| Product Name | AEM anode electrode |

| Substrate | nickel foam |

| catalyst component | Ni-Fe |

| Maximum product size | 500x500mm |

| Storage conditions | Vacuum seal before use |

| 200mA/cm² overpotential | 263mV |

Online consultation

Please leave your contact information to us and we will contact you within 24 hours.